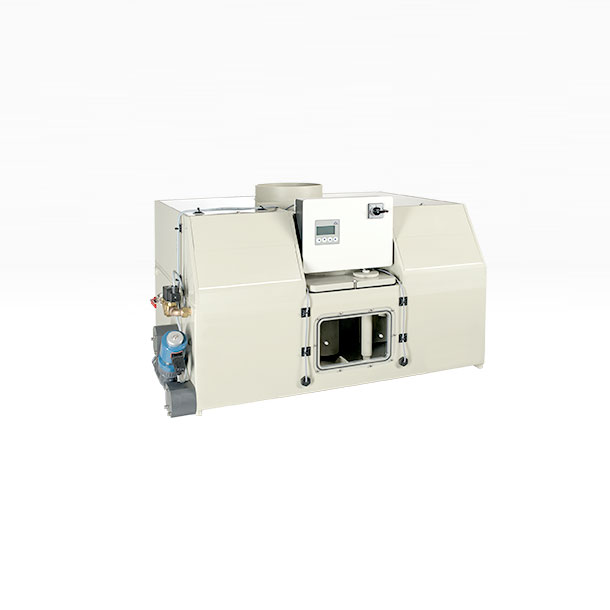

Accessories for fume cupboards

As a leading manufacturer of fume cupboards, we offer a wide range of accessories for fume cupboards. We have a wide range of support elements and accessories which help to achieve better results in terms of safety and energy efficiency when incorporated into our fume cupboards.